Large Circular Saw Blades

Diamond Tools for Large Circular Saw

Diamond Saw Blades, Multi Blades Segments

Saw Blades Ø 1000 – 4200 mm

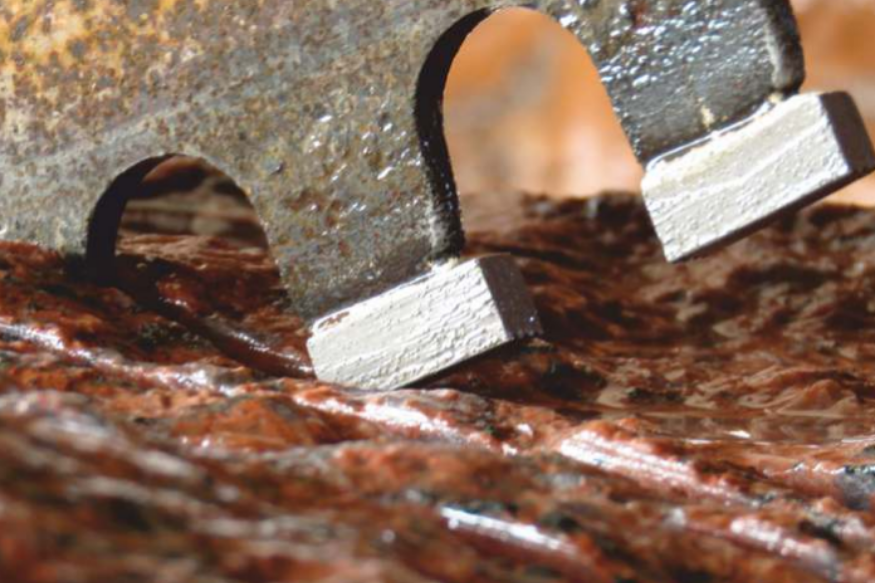

Large Circular Saw Blades are usually re-tipped thus we mostly provide loose segments for these blades. However we can also provide the complete saw with segments, if required. Our segment of these dimensions are very popular. We usually provide sandwich segments and multi layer segments, so as to enable free cutting. Our segments can be used for water cutting & any other lubricants. However we request customers to inform us in advance the cutting medium, so as to design the tool accordingly.

Our segments cut the hardest of the stone, without any load on the machines and the blade. Thus we guarantee free cutting segments with long life.

We have also designed low cost segments in this category and we guarantee free cutting and adequate life for these segments also. Our segments can be manufactured with height ranging from 10 mm upto 30 mm. We proudly state that our segments can absorb any condition of the machine due to its inherent design of smooth cutting and latest state of art technology. We also provide segments of blades of various sizes used on single machine.

As we have an advance R&D and experienced tool designers with special knowledge of metal bonding, our technology gets upgraded from time to time.

Our segments and blades are used for cutting all natural stones such as granite, marble, sand stone, lime stone, slate, basalt and mica etc. As these are large diameter blades, we give special emphasis on the bonding and we supply sandwich as well as box segments. We give complete blades as well as loose segments for this category. These blades are famous for low power consumption and give perfect finish to the slabs and tiles from the block.

STANDARD DIMENSIONS

|

Saw Diameter |

No. of Slots (narrow slot) |

No. of Slots (wide slot) |

Core |

Segment |

Cutting |

Height of Diamond Impregnation (mm) |

|

1000 |

-s |

70 |

5.0 |

23/24 |

7.0 |

10-30 |

|

1100 |

– |

74 |

5.5 |

23/24 |

7.0/7.5 |

10-30 |

|

1200 |

– |

80 |

5.5 |

23/24 |

7.5/8.0 |

10-30 |

|

1250 |

– |

84 |

5.5 |

23/24 |

7.5/8.0 |

10-30 |

|

1300 |

– |

88 |

6.0 |

23/24 |

7.5/8.0 |

10-30 |

|

1350 |

– |

88 |

6.0 |

23/24 |

7.5/8.0 |

10-30 |

|

1600 |

– |

104 |

6.5/7.0 |

23/24 |

9.0/9.5 |

10-30 |

|

1800 |

– |

120 |

7.0 |

23/24 |

9.5/10.0 |

10-30 |

|

2000 |

* |

128 |

7.5/8.0 |

23/24 |

10.0/10.5 |

10-30 |

|

2200 |

– |

132 |

8.0 |

23/24 |

10.5 |

10-30 |

|

2500 |

– |

140 |

9.0 |

23/24 |

11.0/12.0 |

10-30 |

|

3000 |

– |

160 |

9.0 |

23/24 |

12.0/12.5 |

10-30 |

|

3500 |

– |

180 |

9.0 |

23/24 |

12.0/12.5 |

10-30 |

Large circular saw blades